Sever Pharma Solutions offers the solution for companies that need CMO capacity concerning the aseptic filling of syringes and assembly and packaging of pre-filled syringes and auto-injectors. We will enhance your product by adding value through manufacturing if you require short-term access to additional capacity or a complete technology transfer. We use single-use materials to prevent contamination and to ensure operators’ safety.

Sever Pharma Solutions’ aseptic fill and finish capabilities handling high-potent APIs include aseptic filling of syringes, made available in nests and tubs, ranging from 0,2 ml to 50 ml , testing and assembly of pre-filled syringes in auto-injectors. We handle compounding isolators, filling isolators, and solution handling from a disposable bag via single-use tubing.

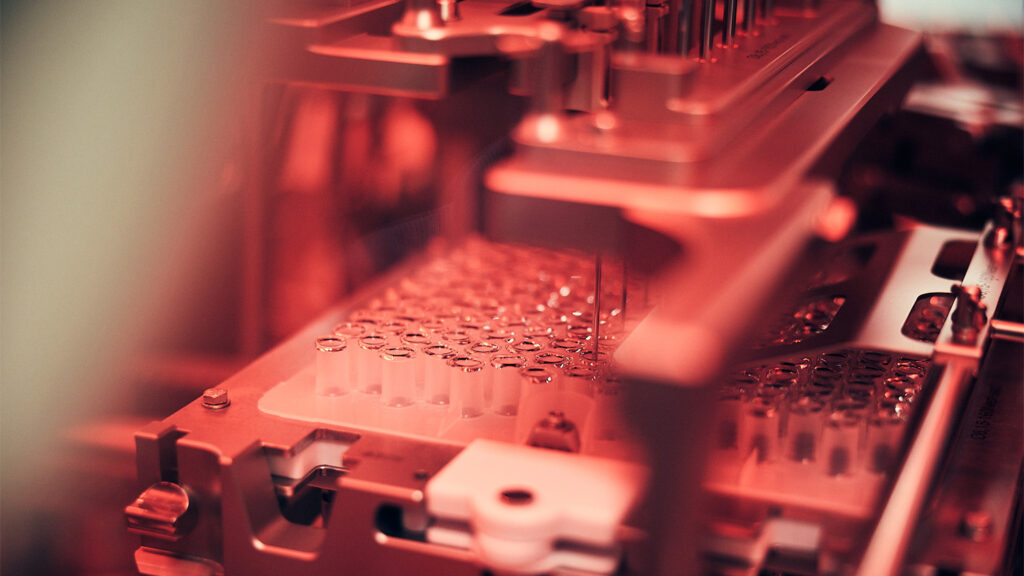

Our capabilities within aseptic filling include a state-of-the-art automatic aseptic filling machine performed in an isolator of syringes, available in nests/tubs with an option of filling with nitrogen flushing during stoppering. We can handle filling 1 ml syringes, volumes of 0.2 – 50 ml. with a max capacity. 8,000 syringes/hour. We also provide you with:

We perform testing by visual inspection and full analytical testing by an in-house analytical lab.

Sever Pharma Solutions offer assembly of pre-filled syringes in auto-injectors* and automated assembly into autoinjector devices. We have two manufacturing lines available with a capacity of max. 40 devices/minute. We offer secondary packing into multiple Stock Keeping Units (SKU) and serialization as an additional service.

*Other devices might require additional equipment.